Engineering

IdaBot

IdaBot

Precision agriculture techniques hold much promise for Idaho specialty crops and will potentially allow growers to maximize yield while controlling crop input costs. While precision agriculture holds great promise, it is challenging to implement in specialty crops because managing specialty crops, such as apples or grapes, typically requires significant manual labor.

About IdaBot

For example, it is not uncommon for grapes and other fruit to be pruned and/or harvested by hand. Even the seemingly simple task of estimating fruit yield can consume multiple days of a laborer’s time since the fruit on the trees must be manually counted. Therefore, precision agriculture techniques add to an already expensive manual labor burden that specialty crop growers must shoulder. One way that labor costs can be reduced and labor-intensive precision agriculture techniques made feasible is through the use of automation. Robots can cheaply do many manual-labor tasks and significantly enhance the productivity of the specialty crop laborer. While the agriculture industry has seen significant innovation in robotics, many of these robots are intended for standard row-planted crops (e.g., self-driven combines). Therefore, there is a need for robots tailored specifically for the specialty crops grown in Idaho.

The purpose of this research project was to design and prototype the IdaBot – a low-cost, autonomous utility robot to assist Idaho specialty-crop growers in the day-to-day maintenance and harvesting of their crops. Although the IdaBot could be used to perform a variety of tasks in both orchards and vineyards, the goal of the first IdaBot prototype is to demonstrate: autonomous navigation of a vineyard and precision application of chemicals to grape vines to reduce waste from overspray.

The remainder of this page provides a high-level overview of the IdaBot project; however, this project is only part of NNU’s focus on engineering in agriculture. Please see NNU’s agriculture engineering concentration and this video from the Voice of America highlighting the IdaBot and other agriculture-related research at NNU.

Overview

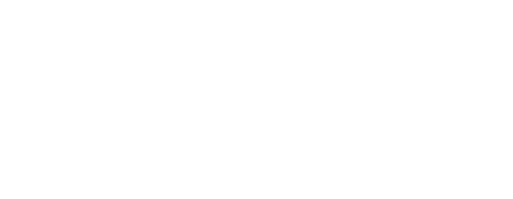

The IdaBot prototype was built upon a relatively small, track-driven robotic platform purchased from SuperDroid Robots, shown in Figure 1. In its unmodified form, the robotic platform could be driven with a remote control, but in this project, the robot was outfitted with sensors, controllers, an RFID reader, and a small tank sprayer to allow it to autonomously navigate and apply chemicals in a vineyard. The final IdaBot prototype is shown in Figure 2. Although the robotic platform and tank sprayer are certainly smaller than what would needed for day-to-day farm use, they provide an easy means to demonstrate how RFID can be used to autonomously navigate a robot through a vineyard or orchard and apply chemicals in specific locations without the need to work with large equipment. The techniques demonstrated on this small prototype of the IdaBot can be transferred to other, larger vehicles.

The final IdaBot prototype shows the robotic platform, embedded electronics (microcontrollers and sensors), the RFID reader antennas, and the tank sprayer. One of the RFID tags was mounted on the grape trellis row to allow the IdaBot to autonomously navigate.

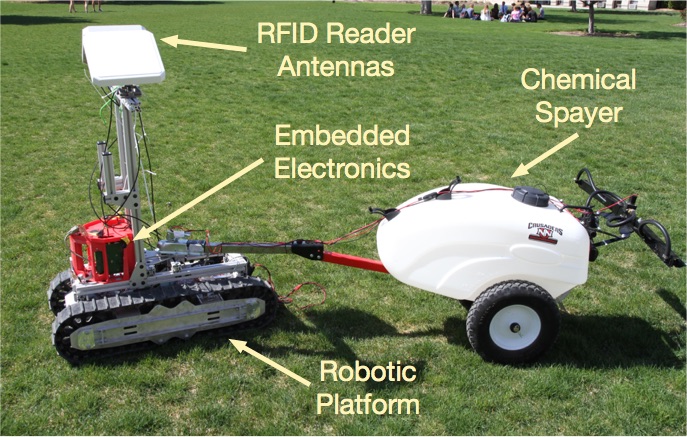

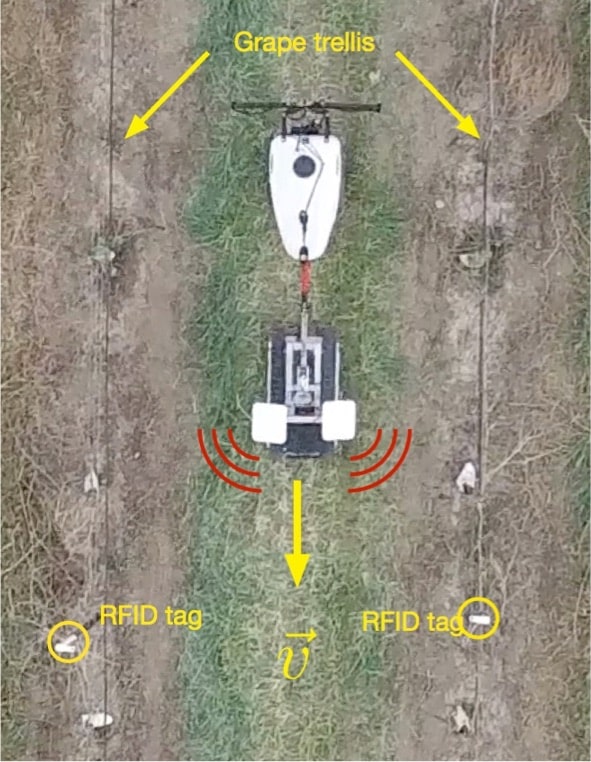

The RFID tags are mounted above the grape trellis on white poles. Three pairs of tags can be seen. An aerial view of the Idabot navigating a grape trellis row at Williamson Vineyard.

Learn More

The IdaBot prototype autonomously navigates by following a heading providing by a magnetic compass and determining the distance that it has traveled using motor encoders. While these sensors may, in principle, allow the robot to autonomously navigate, they are prone to errors that accumulate with the distance traveled. For example, if the tracks of the robot slip on soft dirt, the encoders may report that the robot has traveled some distance, while, in fact, the robot has not moved at all. Therefore, an RFID system is used to provide error corrections to the robot so that it can accurately determine the distance that it has traveled and also determine when it is adjacent to a particular vine or tree. The RFID navigation system works as follows: small, passive RFID tags (shown in Figure 3) are placed above the grape trellis (or on an orchard tree), as shown in Figure 4. The RFID tags are passive (i.e., they do not contain a power source) and are encapsulated in plastic, allowing them to remain in the vineyard or orchard for many years without maintenance. The RFID tags are read by an RFID reader mounted on the IdaBot. By applying a spatial-averaging algorithm to the phase of the radio frequency signals received from each RFID tag, the IdaBot’s distance to each tag can be determined with a resolution of up to 3-4 inches. Since the RFID tags are fixed on the grape trellis, knowing the distance from the IdaBot to each tag allows the IdaBot to remain centered between the grape trellis rows and accurately estimate how far down the trellis row it has traveled.

The IdaBot prototype was tested on the NNU campus and at Bitner and Williamson Vineyards prior to its final demonstration for the public at Williamson Vineyard. In the testing and the demonstration, the IdaBot was able to perform the following:

Read RFID tags attached to the grape trellis and estimate the distance to each tag.

Sense that it was not centered between the grape trellis rows and make a correction.

Accurately estimate the distance traveled down the grape trellis row

Turn on/off the sprayer when passing a certain set of RFID tags

The algorithm used to determine the IdaBot’s distance to each tag employs a modified version of the combined dual-frequency / continuous-frequency radar algorithm developed by Dr. Chenming Zhou at Disney Research in the following papers:

[1] C. Zhou and J. D. Griffin, “Phased-Based Composite Ranging for Backscatter RF Tags: System Analysis and Measurements,” in IEEE Transactions on Antennas and Propagation. Available through IEEEXplore.

[2] C. Zhou and J. D. Griffin, “Accurate Phase-Based Ranging Measurements for Backscatter RFID Tags,” in IEEE Antennas and Wireless Propagation Letters, vol. 11, pp. 152-155, 2012. Available through IEEEXplore or Disney Research.

These abilities form the core of what must be done for the IdaBot to autonomously navigate a vineyard and apply chemicals. Therefore, we consider the IdaBot prototype a success. Of course, much more work is needed to turn the IdaBot prototype into a commercially viable tool for growers. Improvements that may be pursued in future research or a future commercialization effort include:

Transferring the RFID navigation technology to a larger robot platform and a larger sprayer. A small tractor would likely be a good choice.

Optimize the software for speed and robustness.

Modify the RFID distance estimate algorithm to so that can work while frequency hopping (as required by the FCC for commercial use). Frequency hopping was ignored for the IdaBot prototype to simplify this proof-of-concept project.

Project Team Members

Lucas A. Pomeroy – Student

Richard E. Grindstaff III – Student

Cole Logemann – Student

Quentin Fredrick – Student

Dr. Joshua Griffin – PI

Dr. Duke Bulanon – Co-PI